1. Raw Polyethylene

At 3A Manufacturing we produce all of our own bubble wrap, starting with the base materials.

2. Polyethylene

Plastic resin, compounded to our specification is mixed with other additives.

3. Other Additives

As much in house waste is recycled as possible. Mixed with new material it is fed into the film machine, heated, melted and extruded as thin sheets.

4. Bubble Wrap Lamination

Air pockets are vacuum formed on the thin sheets at high speed to create individual bubbles.

5. Rolled into bulk

The bubble film sheet is wound into ‘jumbo’ sized rolls in a continuous process.

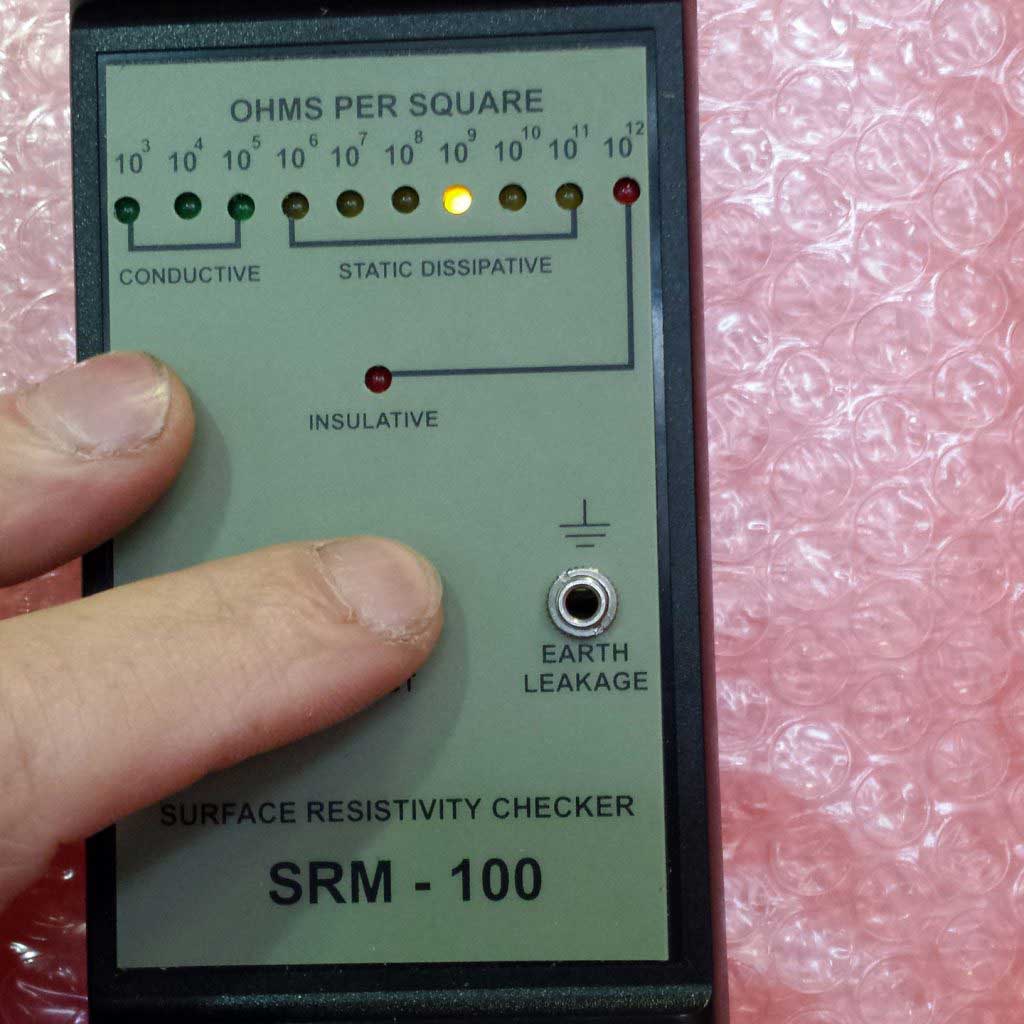

6. Antistatic Tests

Antistatic bubble wrap is tested for conductivity and static dissipation.

7. Ready for Distribution

Rolls ready for distribution and conversion into bubble bags.